BALL MILL SPARE PARTS

Key Specifications / Features

Model No.: Hits: 24

Compatible with mainstream ball mill models, crafted from high-wear-resistant alloy material, it reduces operational losses, ensures continuous and stable equipment operation, and improves production efficiency.

Request a quote

PDF

Tags:

Detail Information

Slag Pot |

High-strength heat-resistant alloy slag pot safely transports molten slag. Sealed design prevents leakage; resists 1200℃+ temperatures, ensuring operational safety and reducing downtime. |

Girth Gear |

Core transmission part of high-carbon alloy cast steel. Precise meshing enables smooth power transfer, wear-resistant, extends service life by 25%, and boosts grinding efficiency. |

Pinion Shaft |

Forged alloy steel power component. High-precision machining ensures tight meshing with girth gear, load-bearing and wear-resistant, guaranteeing stable mill operation. |

Liner Plate |

High-chromium alloy/wear-resistant cast iron liner. Protects mill cylinder and enhances grinding effect; HRC≥60, 30% longer service life, cutting maintenance costs. |

Grinding Media |

High-chromium alloy spherical media. Uniform hardness and strong impact toughness improve grinding efficiency, reducing consumption and operational costs. |

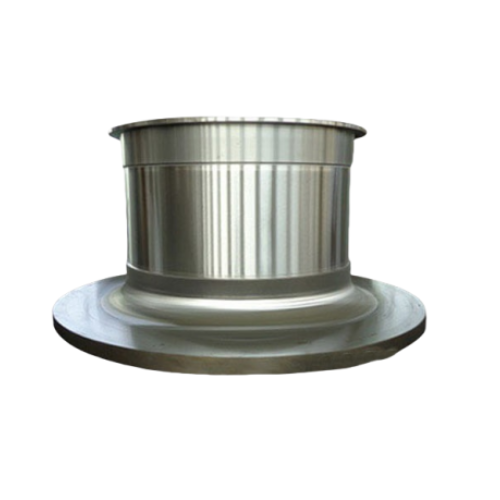

Trunnion |

High-strength cast steel supporting component. Bears mill weight for smooth rotation, sealed to prevent leakage, ensuring stable operation under harsh conditions. |