QC Team of SINOSPARE Issued a Report of SINOSPARE's Filter Bags

The QC team of SINOSPARE issued a QC inspection report of SINOSPARE's filter bags.

For ensuring the quality control of the filter bags ordered by Pakistan clients, the quality control team of SINOSPARE offered a survey report on the filter bags according to the following news and methods of production.

Filter Bag Market in China

China is now carrying out the strictest air pollution control. Exhaust gas discharges by any factory should be purified before releasing to the atmosphere, otherwise the factory would be shut down by the Chinese Government if the amount of pollution is alerted by the government's on-line air quality monitoring system.

The fast production among factories right now creates a huge demand of filter bags. Because of that, every material using in manufacturing bags is rising in price. Besides, some first-rate fiberglass materials are also in short supply.

Delivery Schedule of 1000 Pieces of Filter Bags at SINOSPARE - Order Handling Procedures

For ensuring the quality control of the filter bags ordered by Pakistan clients, the quality control team of SINOSPARE offered a survey report on the filter bags according to the following news and methods of production.

Filter Bag Market in China

China is now carrying out the strictest air pollution control. Exhaust gas discharges by any factory should be purified before releasing to the atmosphere, otherwise the factory would be shut down by the Chinese Government if the amount of pollution is alerted by the government's on-line air quality monitoring system.

The fast production among factories right now creates a huge demand of filter bags. Because of that, every material using in manufacturing bags is rising in price. Besides, some first-rate fiberglass materials are also in short supply.

Delivery Schedule of 1000 Pieces of Filter Bags at SINOSPARE - Order Handling Procedures

- The completion time of producing the goods will be within 30 days, including product inspection.

- The package will be sent from the factory 30 days after the order confirmed, and reach the port of Xiamen 32 or 33 days later. For overland transport, our company will pay for the fee of overland trucks, whose safety and efficiency are ensured.

- After the container is loaded and cleared, it will be transported by sea as the letter of credit requests.

Fiberglass and Fiberglass Cloth

SINOSPARE uses first-class quality fiberglass for filter bag manufacturing even its cost is rising. Quality of fiberglass and weaving techniques are the key points to stabilize the performance and long-term service life of filter bags.

|

|

|

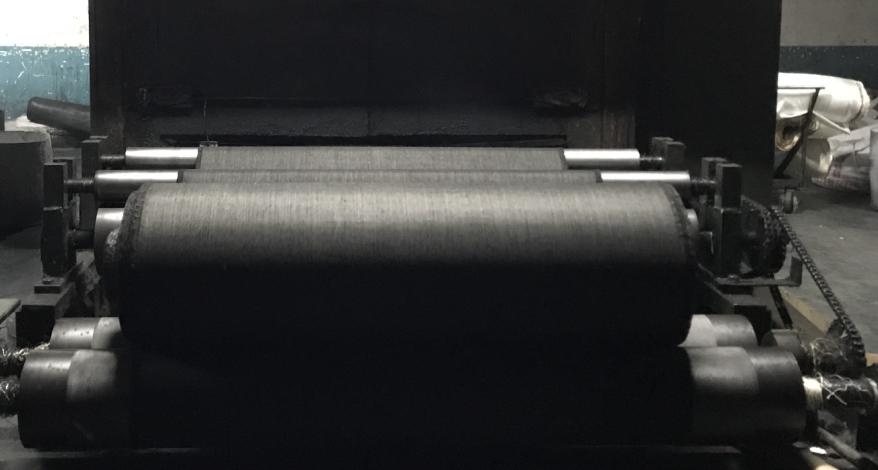

Dewaxing is the pre-process ofgraphiting so as to assure the graphite quality.

|

|

Mechanical capacity and performance of fiberglass dust catching can be stabilized aftergraphiting.

Stitching

Filter bags offered by SINOSPARE are with advanced sewing techniques, which provide straight stitching lines and high density of stitching. Also, high-quality filter bags are with bright and shining surface, which are the results of using top-quality fiberglass and equipment as well as stric controls of the manufacturing process.

|

|

Attitude

SINOSPARE always aims to win trust from global customers.Staff of SINOSPARE are with highly responsibility and earnest to every orders from global clients.