The Finish Treatment Of Filter Bag

Filter bags are known as the heart and key component of dust collector/bag house in de-dusting sector of heavy industry plants, like cement plants, steel plants, asphalt plants, silicon powder plants. In most cases, filter bags are vertically installed inside the dust collector/baghouse, the bag’s material and design should aim to achieve high filtration efficiency, long-term service life and easy ash removing effect.

During the de-dusting process, the dust will be caught on the surface layer of the filter bag when the exhausted gas/smoke passing through the filter bag. Exhaust gas and smoke will be cleaned after being filtered by filter bags. Filter cages are used as a supporter of the filter bag. Meanwhile, cages are also functional for uniform distribution of dust pasting on the surface of filter bags and easy ash removing. Different finishing treatments are needed for special working conditions. Normally, we can do the following finishing treatments for filter bags.

1. Singeing and Calendaring

Burn off cloth's nap by burners and smooth the filter cloth by a high-temperature roller. Filter cloth can achieve easy ash removing effect and ultrafine dust catching effects after singeing and calendaring.

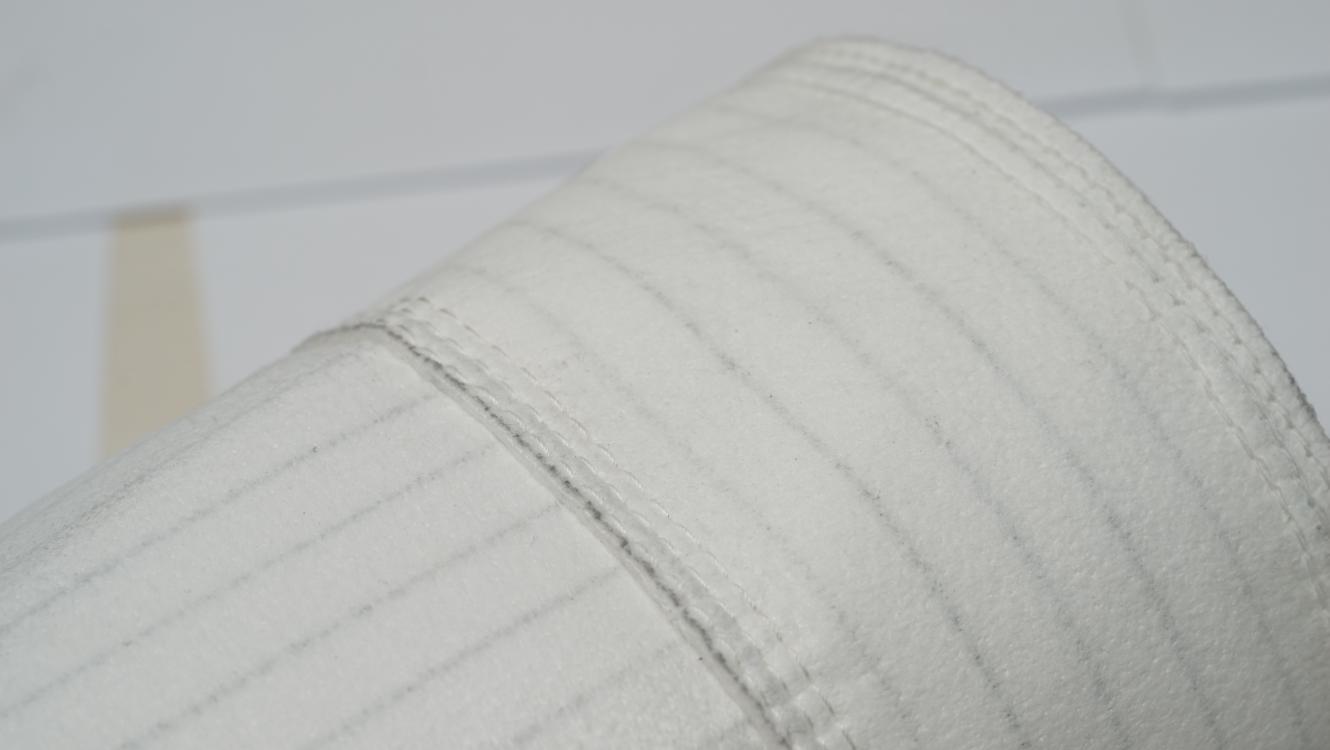

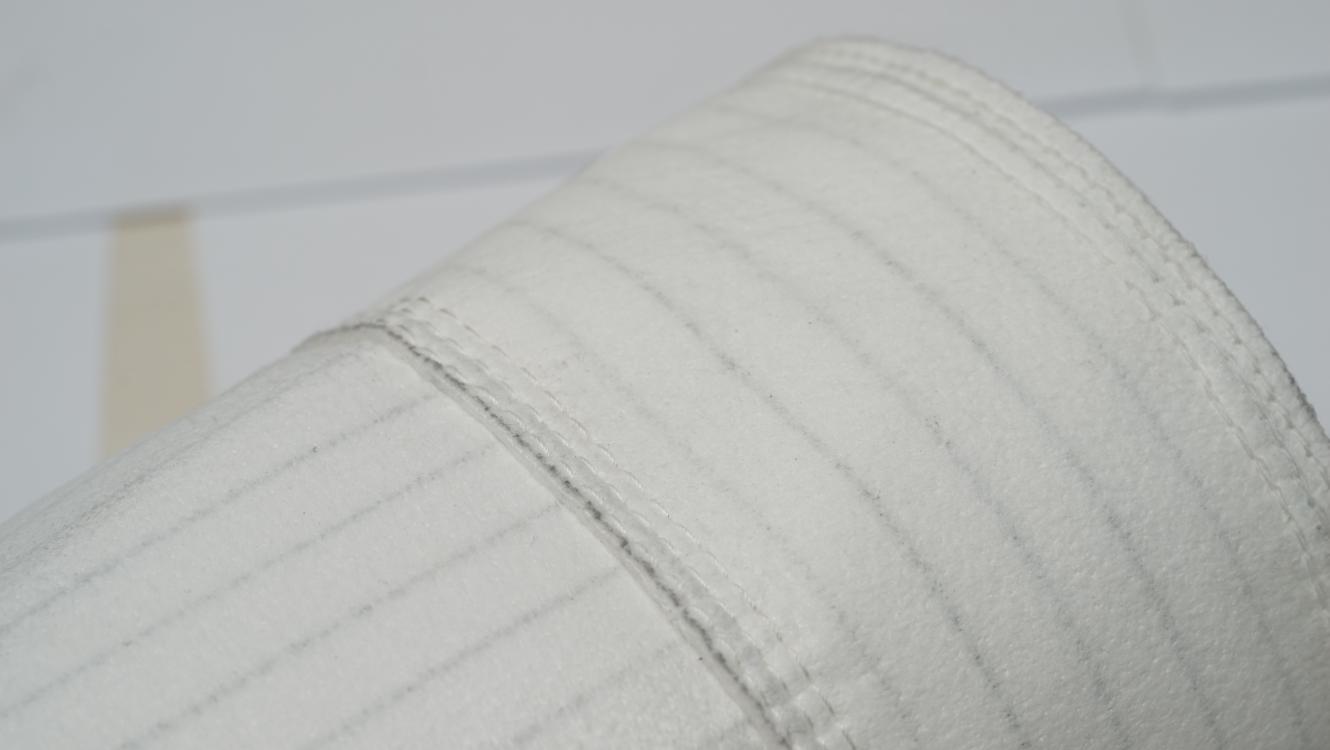

2. Anti-static Treatment

In the filtration of inflammable and explosive dust filtration, the filter cloth should be composited with anti-static fabric or anti-static bar inside the scrim of filter cloth to avoid combustion and explosion.

3. Waterproof and Oil-proof Treatment

Dip needle felt into silicone oil and PTFE emulsion so as to make filter cloth waterproof and oil-proof, water will roll and drip when vapor condenses into water.

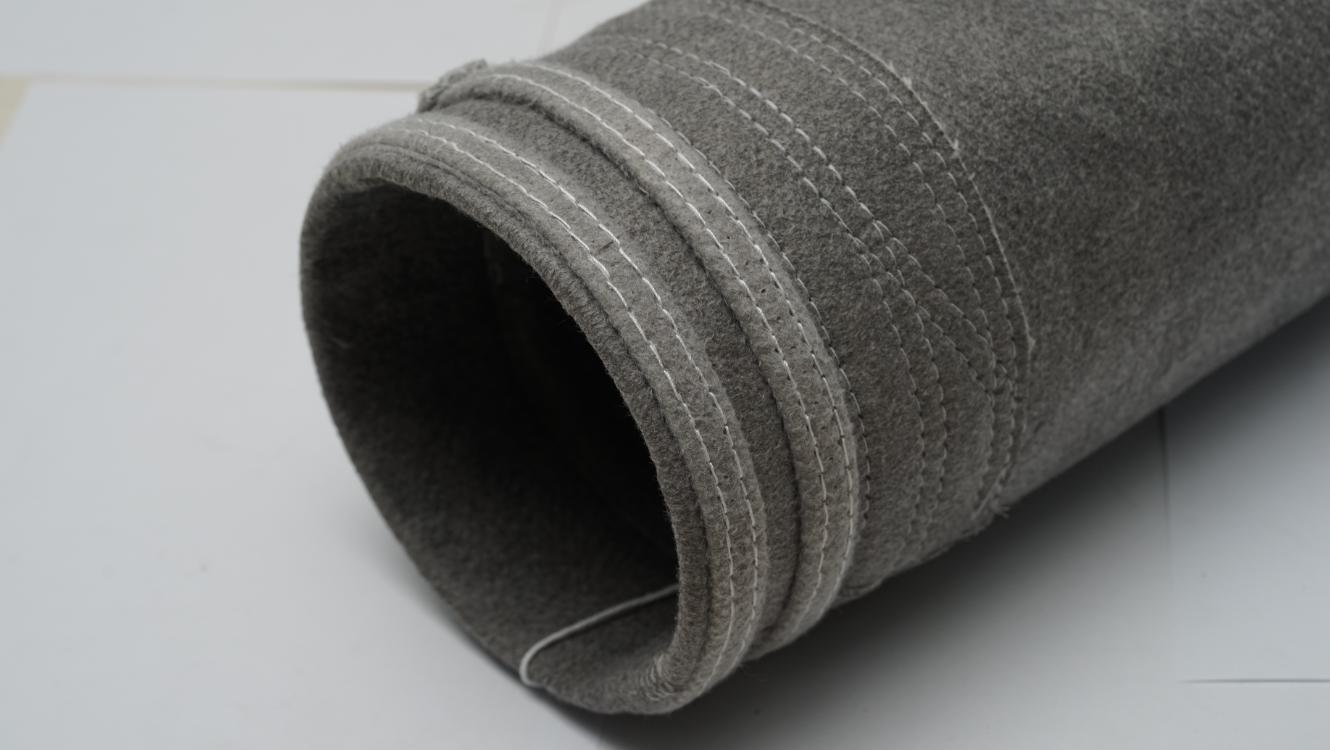

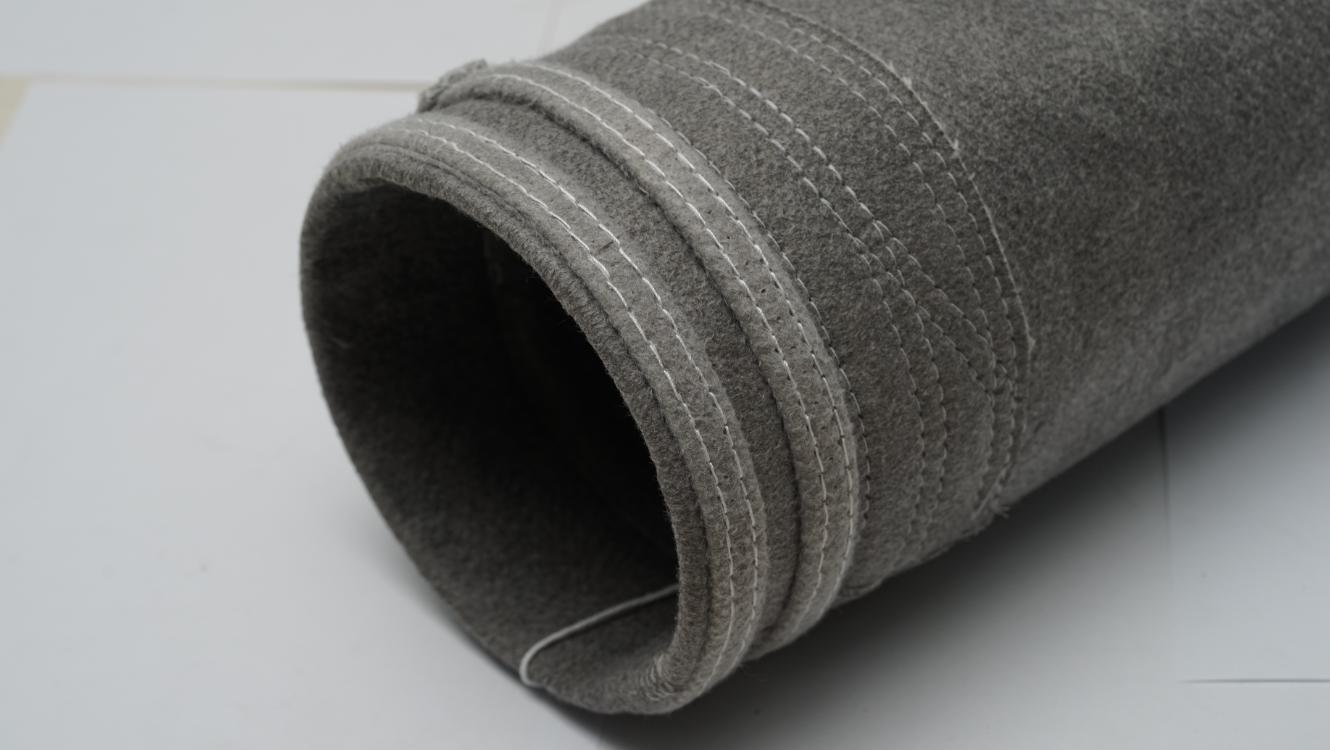

4. Easy Ash Removing Treatment

Not only singeing and calendaring can achieve easy ash removing effect, we process super fine denier fabric needle punched layer as the first and surface layer of the filter bag which can also achieve easy ash removing effects and handle high filtration speed working condition for a long time.

5. PTFE Coating

When the particle size is less than one micron, or the exhausted gas with high sticky dust, or high moisture contained which the ordinary and traditional filter cloth can’t handle. The finishing treatment of PTFE coating aims to make the filter cloth with high accuracy filtration, smoothing surface, anti-sticky dust, easy ash removing and blocking the dust infiltrating inside the filter cloth.

6. Heat Setting Treatment

Heat setting was needed for stress relieving. Filter bags are with stable size and smooth surface after heat setting. Filter bags will be damaged by friction against the filter cages if the size is unstable. Unstable size of the filter bag could also cause problems when installing.

During the de-dusting process, the dust will be caught on the surface layer of the filter bag when the exhausted gas/smoke passing through the filter bag. Exhaust gas and smoke will be cleaned after being filtered by filter bags. Filter cages are used as a supporter of the filter bag. Meanwhile, cages are also functional for uniform distribution of dust pasting on the surface of filter bags and easy ash removing. Different finishing treatments are needed for special working conditions. Normally, we can do the following finishing treatments for filter bags.

1. Singeing and Calendaring

Burn off cloth's nap by burners and smooth the filter cloth by a high-temperature roller. Filter cloth can achieve easy ash removing effect and ultrafine dust catching effects after singeing and calendaring.

2. Anti-static Treatment

In the filtration of inflammable and explosive dust filtration, the filter cloth should be composited with anti-static fabric or anti-static bar inside the scrim of filter cloth to avoid combustion and explosion.

3. Waterproof and Oil-proof Treatment

Dip needle felt into silicone oil and PTFE emulsion so as to make filter cloth waterproof and oil-proof, water will roll and drip when vapor condenses into water.

4. Easy Ash Removing Treatment

Not only singeing and calendaring can achieve easy ash removing effect, we process super fine denier fabric needle punched layer as the first and surface layer of the filter bag which can also achieve easy ash removing effects and handle high filtration speed working condition for a long time.

5. PTFE Coating

When the particle size is less than one micron, or the exhausted gas with high sticky dust, or high moisture contained which the ordinary and traditional filter cloth can’t handle. The finishing treatment of PTFE coating aims to make the filter cloth with high accuracy filtration, smoothing surface, anti-sticky dust, easy ash removing and blocking the dust infiltrating inside the filter cloth.

6. Heat Setting Treatment

Heat setting was needed for stress relieving. Filter bags are with stable size and smooth surface after heat setting. Filter bags will be damaged by friction against the filter cages if the size is unstable. Unstable size of the filter bag could also cause problems when installing.