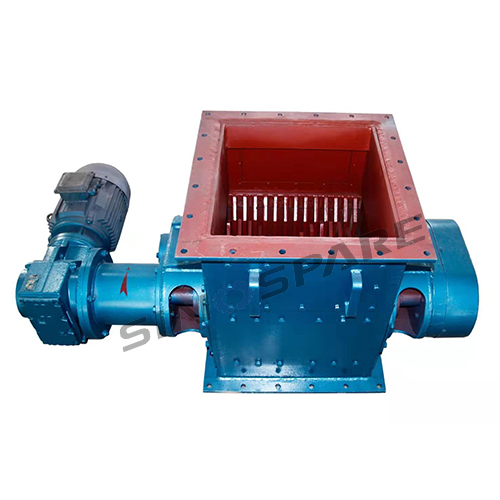

Crushing Valve for Material Distributor

Key Specifications / Features

Model No.: VAG-05 Hits: 561

The block crushing valve is designed and applied to create continuous and steady material flow from the silo and other storage space for powder material by crushing the material block which was affected from damp.

Request a quote

Tags:

Detail Information

Crushing Valve for Material Distributor

The block crushing valve is designed and applied to create continuous and steady material flow from the silo and other storage space for powder material by crushing the material block which was affected from damp.

Material blocking and virtual signal of unreal material flow to the control valve caused by the material blocking when material across the discharge devices. So, the unstable material flow could affect the normal production of the processing system, or maybe because of false signal caused a serious imbalance between the ratio between the raw material and fuel, resulting in the high temperature of combustion equipment, equipment accidents.

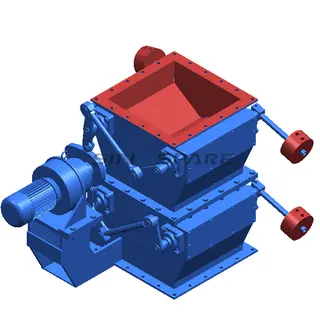

Block crushing valve can be installed horizontally or vertically at the unloading outlet to the feeding end of unloading equipment, such as the front of the flow regulating valve or pneumatic switching valve. When there is a large bulk material in the material flow, it can be crushed immediately, to prevent the bulk material from blocking the discharge valve channel and ensure smooth discharge.

The rotor of the crushing valve is equipped with the radial crushing claw, which can move the block material through the grid and break it.

Control requirements: when both forward and reverse turns are stuck, the broken valve should stop and wait for troubleshooting before running.

The safety-ensuring of the block crushing valve is guaranteed by the motor speed and motor current detection device integrated in the electric control box. When certain blocks in the material cannot be crushed and the rotor is stuck, the detection device will alarm and automatically reverse, pushing the block that cannot be broken before it is turned forward.

Note: this configuration is an optional function that needs to be proposed when ordering.

Design Features

1. The throughput of the largest model can reach 1000m3/h.

2.Suitable for all kinds of air-operated chute and storage discharge outlet.

3. The maximum temperature of the material can reach 120℃.

4. Low energy consumption, drive motor power below B500 is 3kw, and above B600 is 4kw.

5.Broken claw and grille board material for the first class of wear-resistant materials.

6.Simple maintenance.

7.Integrated speed and current detection device and electronic control (optional)

Technical performance table for horizontal installation of crushing valves (Type H)

Note: The passing capacity is the reference value which are affected by the lower part of the crushing valve is the fluidized air volume and wind pressure, the chute passing capacity of the supporting interface of the broken valve shall prevail.

Vertical installation of broken valve technical performance table

The block crushing valve is designed and applied to create continuous and steady material flow from the silo and other storage space for powder material by crushing the material block which was affected from damp.

Material blocking and virtual signal of unreal material flow to the control valve caused by the material blocking when material across the discharge devices. So, the unstable material flow could affect the normal production of the processing system, or maybe because of false signal caused a serious imbalance between the ratio between the raw material and fuel, resulting in the high temperature of combustion equipment, equipment accidents.

Block crushing valve can be installed horizontally or vertically at the unloading outlet to the feeding end of unloading equipment, such as the front of the flow regulating valve or pneumatic switching valve. When there is a large bulk material in the material flow, it can be crushed immediately, to prevent the bulk material from blocking the discharge valve channel and ensure smooth discharge.

The rotor of the crushing valve is equipped with the radial crushing claw, which can move the block material through the grid and break it.

Control requirements: when both forward and reverse turns are stuck, the broken valve should stop and wait for troubleshooting before running.

The safety-ensuring of the block crushing valve is guaranteed by the motor speed and motor current detection device integrated in the electric control box. When certain blocks in the material cannot be crushed and the rotor is stuck, the detection device will alarm and automatically reverse, pushing the block that cannot be broken before it is turned forward.

Note: this configuration is an optional function that needs to be proposed when ordering.

Design Features

1. The throughput of the largest model can reach 1000m3/h.

2.Suitable for all kinds of air-operated chute and storage discharge outlet.

3. The maximum temperature of the material can reach 120℃.

4. Low energy consumption, drive motor power below B500 is 3kw, and above B600 is 4kw.

5.Broken claw and grille board material for the first class of wear-resistant materials.

6.Simple maintenance.

7.Integrated speed and current detection device and electronic control (optional)

Technical performance table for horizontal installation of crushing valves (Type H)

| Type | Effective Size(mm) | Capacity (m3/h) |

Max Block Size (mm) |

Fluidization Pressure (Kpa) | Air Consumption (m/min) |

| LCV250 | 250 | 200 | <150 | ≥30 | 0.19 |

| LCV300 | 300 | 300 | <150 | ≥30 | 0.23 |

| LCV315 | 315 | 325 | <150 | ≥30 | 0.24 |

| LCV350 | 350 | 375 | <150 | ≥30 | 0.26 |

| LCV400 | 400 | 450 | <200 | ≥30 | 0.30 |

| LCV500 | 500 | 600 | <200 | ≥30 | 0.38 |

| LCV600 | 600 | 800 | <200 | ≥30 | 0.45 |

| LCV630 | 630 | 900 | <200 | ≥30 | 0.47 |

| LCV650 | 650 | 900 | <200 | ≥30 | 0.47 |

Note: The passing capacity is the reference value which are affected by the lower part of the crushing valve is the fluidized air volume and wind pressure, the chute passing capacity of the supporting interface of the broken valve shall prevail.

Vertical installation of broken valve technical performance table

| Type | Effective Size (mm) |

Capacity (m3/h) |

Max Block Size (mm) |

| 400x400 | 400x300 | 500 | 200 |

| 500x500 | 500x400 | 800 | 200 |

| 600x600 | 600x500 | 1000 | 200 |