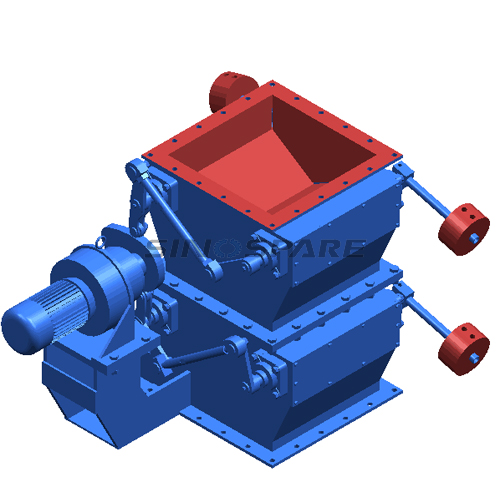

Custom Double Flap Valve for Cement Plant

Key Specifications / Features

Model No.: VAG-02 Hits: 350

Custom Double Flap Valve supplier in China provides customized double dump valve as a component for bulk material handling applications in cement plant and other heavy industries.

Tags:

Next: Rotary Airlock Valve

Detail Information

Double dump valves, also known as double flap valves or double flap gates, are a type of airlock valves commonly used in industrial applications as a component in bulk material handling applications. There are single flap gate dump valves and double flap gate dump valves on the market with gravity-fed, motorized or pneumatic flap control methods. Flap gate dump valves are primarily used to discharge bulk materials from hoppers, bins, and silos operating under positive or negative pressure. Double dump valves are used to discharge a flow of material while at the same time serving as an airlock transition point to preserve the pressure differential above and below the valve. This type of material handling valve is ideal for use with bulky or abrasive materials that would tend to jam or damage a rotary feeder.

FEATURES & BENEFITS

• A wide range of customer options - single dump, double dump, square or tube type valve; gravity-fed, motorized, pneumatic control methods

• Made of high-quality steel plate welded

• Stable operation

• Energy consumption saving

• Convenient adjustment

• Reliable airlock

• Reliable discharge ability

• Customized manufacturing

APPLICATIONS

• The bulk material airlock discharges or connects for bag collector, baghouse, silosand sealed conveying system

• Bulk material handling for any kind of dry dust, granule, crystal material

• Operating temperature: 150℃

• Capacity: 3~178 m³/h

FEATURES & BENEFITS

• A wide range of customer options - single dump, double dump, square or tube type valve; gravity-fed, motorized, pneumatic control methods

• Made of high-quality steel plate welded

• Stable operation

• Energy consumption saving

• Convenient adjustment

• Reliable airlock

• Reliable discharge ability

• Customized manufacturing

APPLICATIONS

• The bulk material airlock discharges or connects for bag collector, baghouse, silosand sealed conveying system

• Bulk material handling for any kind of dry dust, granule, crystal material

• Operating temperature: 150℃

• Capacity: 3~178 m³/h

SPECIFICATION

| Performance Parameter of Double Dump Valves | ||

| Media | Suitable Temp | Discharge Capacity |

| Dry Dust, Granule, Crystal Materials | ≤150℃ | 3~168m³/h |