Stainless Steel Reaction Vessel for Cement Plant

Key Specifications / Features

Model No.: RV-01 Hits: 182

China stainless steel reaction vessel supplier offers durable custom stainless steel reaction vessel, continuous stirred tank reactor for cement plant.

Request a quote

Tags:

Detail Information

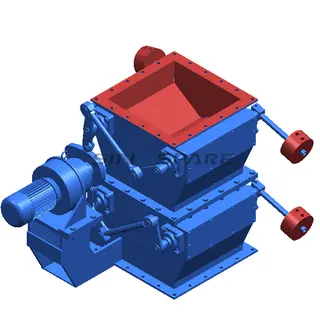

The reaction vessel is a traditional production equipment in the chemical, pharmaceutical and other industries and plays an important role in traditional processes such as liquid-liquid mixing and liquid-powder mixing. According to the needs of customers, various mixing paddles can be prepared to achieve different reaction effects. The capacity, dimensions and feeding method of the reactor can be designed according to the site environment and the production process. It is a necessary production equipment for the traditional chemical industry. The reactor offered by our company consists of upper and lower heads, inner cylinder, jacket (inner coil, outer disc half tube), agitator, shaft seal, stirring transmission and support, etc. Production process, operating conditions, jacket heating type can be divided into electric heating rod heating, steam heating, heat conduction oil heating, shaft sealing device can be divided into packing sealing and mechanical sealing. Stirring types are anchor type, slurry type, worm wheel type, propulsion type and frame type. The number of holes, specifications, materials or other requirements can be designed and manufactured according to user requirements. High-efficiency reaction of flammable, explosive, highly toxic, hydrogen, hydrofluoric acid and other harsh media.

FEATURES & BENEFITS

• Static sealing, no leakage, no noise, no pollution, stable operation, simple operation, sturdy and durable and compact structure

• Being able to react under high temperature, high pressure, high vacuum, high speed, suspension and convection.

• The medium is completely in a static sealed state, and it is safe to carry out.

APPLICATION

Widely used in college and university laboratory, petrochemicals, dyes and metallurgy, nanomaterials, polymer reactions, hydrothermal synthesis, hydrogenation reactions, national defence technology, pharmaceutical and food, cigarette industry, ceramics, polymer industry, fine chemicals, microbial engineering, high-tech products and other fields.

SPECIFICATION

FEATURES & BENEFITS

• Static sealing, no leakage, no noise, no pollution, stable operation, simple operation, sturdy and durable and compact structure

• Being able to react under high temperature, high pressure, high vacuum, high speed, suspension and convection.

• The medium is completely in a static sealed state, and it is safe to carry out.

APPLICATION

Widely used in college and university laboratory, petrochemicals, dyes and metallurgy, nanomaterials, polymer reactions, hydrothermal synthesis, hydrogenation reactions, national defence technology, pharmaceutical and food, cigarette industry, ceramics, polymer industry, fine chemicals, microbial engineering, high-tech products and other fields.

SPECIFICATION

| Nominal Volume (m3) |

ID(φmm) | Jacket Diameter (φmm) |

Height (mm) |

Rated Power (kW) |

Agitating (r/min) |

| 3.2 | 1400 | 1500 | 1850 | 1.5-30 | 10-750 |

| 1600 | 1700 | 1300 | |||

| 5 | 1600 | 1700 | 2200 | 1.5-37 | 8-750 |

| 1800 | 1900 | 1650 | |||

| 6.3 | 1600 | 1700 | 2850 | 1.5-45 | 8-750 |

| 1800 | 1900 | 2200 | |||

| 10 | 1800 | 1900 | 3650 | 1.5-55 | 8-750 |

| 2000 | 2100 | 2850 | |||

| 2200 | 2300 | 2300 | |||

| 20 | 2200 | 2300 | 4950 | 3-75 | 6-500 |

| 2600 | 2700 | 3350 | |||

| 25 | 2400 | 2500 | 5150 | 3-90 | 4-400 |

| 2800 | 2900 | 3600 | |||

| 32 | 2600 | 2700 | 5600 | 3.5-90 | 4-400 |

| 3000 | 3100 | 4000 | |||

| 40 | 2800 | 2900 | 6000 | 3.5-90 | 4-400 |

| 3200 | 3300 | 4450 | |||

| 50 | 3000 | 3100 | 6550 | 7.5-110 | 4-320 |

| 3200 | 3300 | 5650 | |||

| 3400 | 3500 | 4900 | |||

| 63 | 3200 | 3300 | 7300 | 7.5-132 | 4-250 |

| 3600 | 3700 | 5550 | |||

| 80 | 3200 | 3300 | 9400 | 11-132 | 4-250 |

| 3600 | 3700 | 7250 | |||

| 100 | 3600 | 3700 | 9200 | 11-132 | 4-200 |